The fascinating world of wood – for the whole world!

W O O D

Wood can address the greatest challenges of our time.

Because wood is an all-rounder and offers answers to today’s most pressing issues.

And much more:

Wood protects

the climate.

They also provide a renewable raw material for the construction industry.

And it’s brilliant.

Whether as round timber or structural timber, wood stores CO₂ in the long term.

Over many decades.

This is

desperately

needed.

Because the construction industry generates

of global CO₂ emissions.

* IEA International Energy Agency -

Global Status Report for Building and Constructions 2019

Wood

is one of

the solutions on the road to climate neutrality.

One positive side effect: residual timber that is not utilised for the construction industry is used to produce eco-friendly energy sources, such as pellets.

In 2050, around of people will live in cities. In 2014, it was only 54%

So high-density building requirements are increasing massively.

Wood overcomes

this too.

Wooden high-rises grow to unimaginable heights.

Existing buildings are easily extended or supplemented with wood,

and timber constructions are a quick and low-emissions way of filling vacant lots.

That means wood belongs in the city. Because it promotes people’s wellbeing. And that’s important – especially in dense cities.

Wood overcomes

urbanisation

Wood is naturally high-tech:

lightweight, yet capable of bearing heavy loads.

Pressure-resistant and moisture-regulating, with high thermal insulation properties.

Wood is the

most ingenious building material

in the world.

Wood is easy to work with and requires little energy.

Prefabricated components and elements lessen the effort required on the construction site and shorten building times.

The likes of modular buildings can be prefabricated to a high degree, scaled and reused, too.

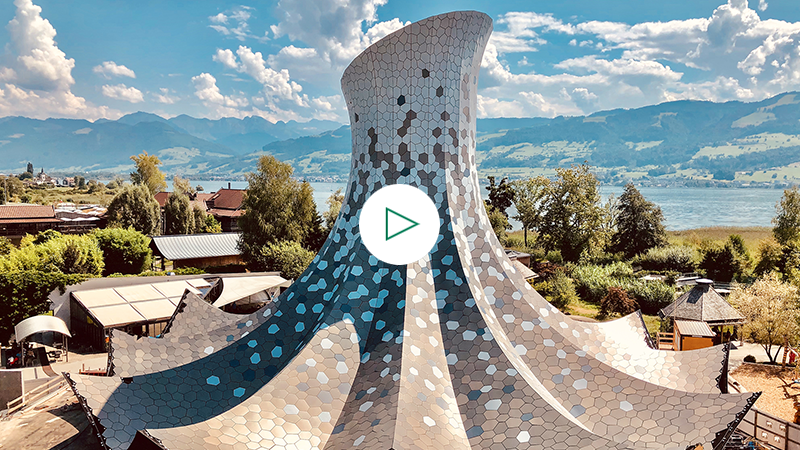

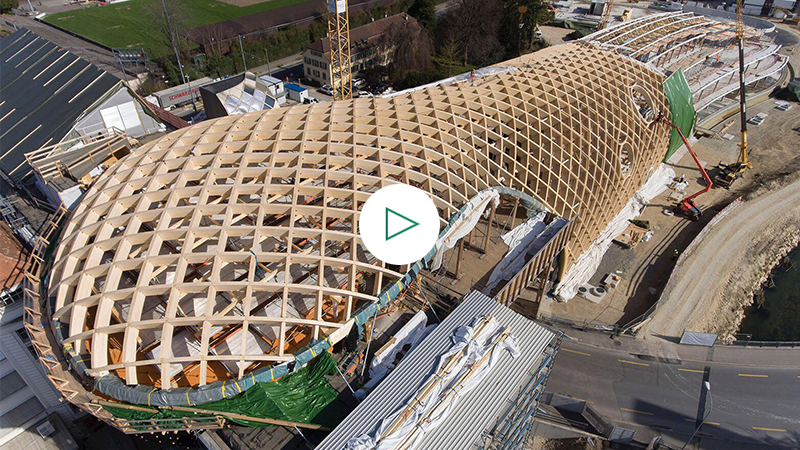

New technologies enable creation of seemingly impossible Free Form structures. Fascinating support structures that are rightly considered the elite class in timber construction.

It’s the people who make the difference.

The technical possibilities of timber construction are fascinating.

But it’s the people who make cutting-edge technology brilliant.

Passionate individuals and dedicated teams who take an unblinkered approach to collaboration

and grow beyond their disciplines.

Programmers who understand wood.

And wood experts who think like programmers.

That’s how pioneering solutions are created – hand in hand.

The future is cyclical.

The age of wastefully using energy- resources is over.

Today, circular systems that no longer create waste are in demand.

Just like wood as a material.

It’s showtime!

See for yourself how wood makes the impossible possible.

Discover and be inspired by all aspects and dimensions of timber construction.

Clear the stage.

Magic load capacity

Magician's hat

A milestone in history of timber construction

Swatch headquarters

Timber modules for Germany

Example of a school building

Blumer Lehmann’s creations are made with wood from sustainable forestry. For projects all over the world. In all dimensions. And, with every challenge, we push the boundaries of what is possible. For a better, more sustainable world.